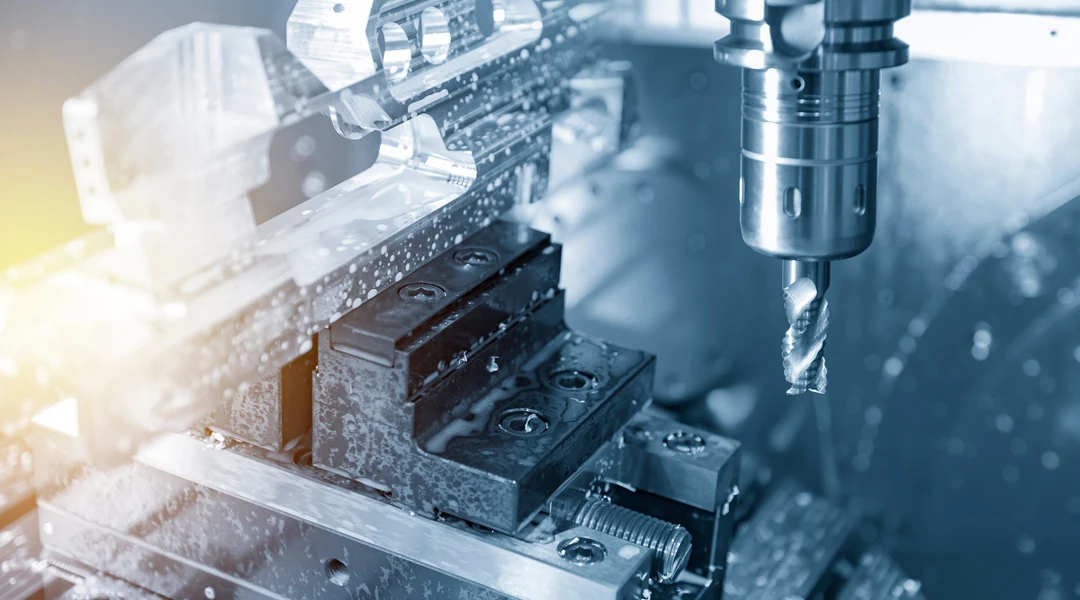

Cutting tools (also known as cutters)

are tiny shanks with sharp cutting edges. Unlike ordinary cutting tools that dissect materials, such as blades, these cutters are used to remove stock from materials during an industrial cutting or machining operation. Because the workpieces cut by the cutting tools are typically hard and stiff, the cutting tool must be rigid enough to perform the machining duties. So, what are solid carbide cutting tools? Read the article to know about solid carbide cutting tools in detail.

Solid carbide drills and end mills are specialized cutting tools that are commonly used in the manufacturing industry. They are made from a single piece of tungsten carbide, a material that is known for its hardness and durability.

Solid carbide drills are used for drilling holes in a variety of materials, including metals, plastics, and composites. They are particularly useful for drilling through hard materials, as they can withstand high temperatures and maintain their sharpness for longer periods of time compared to traditional drill bits. They are also more precise and accurate than other types of drill bits, which makes them ideal for drilling holes with tight tolerances.

End mills, on the other hand, are used for milling and cutting various materials, including wood, metal, and plastic. They have cutting edges on the end and the sides, which allows them to cut in multiple directions. They are also available in a variety of shapes and sizes to suit different applications.

One of the main advantages of solid carbide tools is their durability. They can withstand high temperatures and maintain their sharpness for longer periods of time compared to other types of cutting tools. This makes them ideal for high-speed machining and other demanding applications.

Another advantage of solid carbide tools is their precision. They are able to maintain tight tolerances and produce accurate cuts, which makes them ideal for use in the aerospace and medical industries.

There are some downsides to using solid carbide tools, however. They are generally more expensive than other types of cutting tools, and they can be more difficult to sharpen or repair when they become worn. Additionally, they are not suitable for cutting certain materials, such as aluminium or copper.

In conclusion, solid carbide drills and end mills are specialized cutting tools that are commonly used in the manufacturing industry. They are made from a single piece of tungsten carbide, a material that is known for its hardness and durability. They have many advantages over traditional cutting tools, including precision, durability and resistance to high temperatures, however, they are more expensive and less suitable for certain materials.

We have launched our new series of Solid Carbide Drills and End mills under the IT Carbomach brand and are available via our vast channel. It is precise and made for high performance

1 thought on “What are Solid Carbide Cutting Tools?”