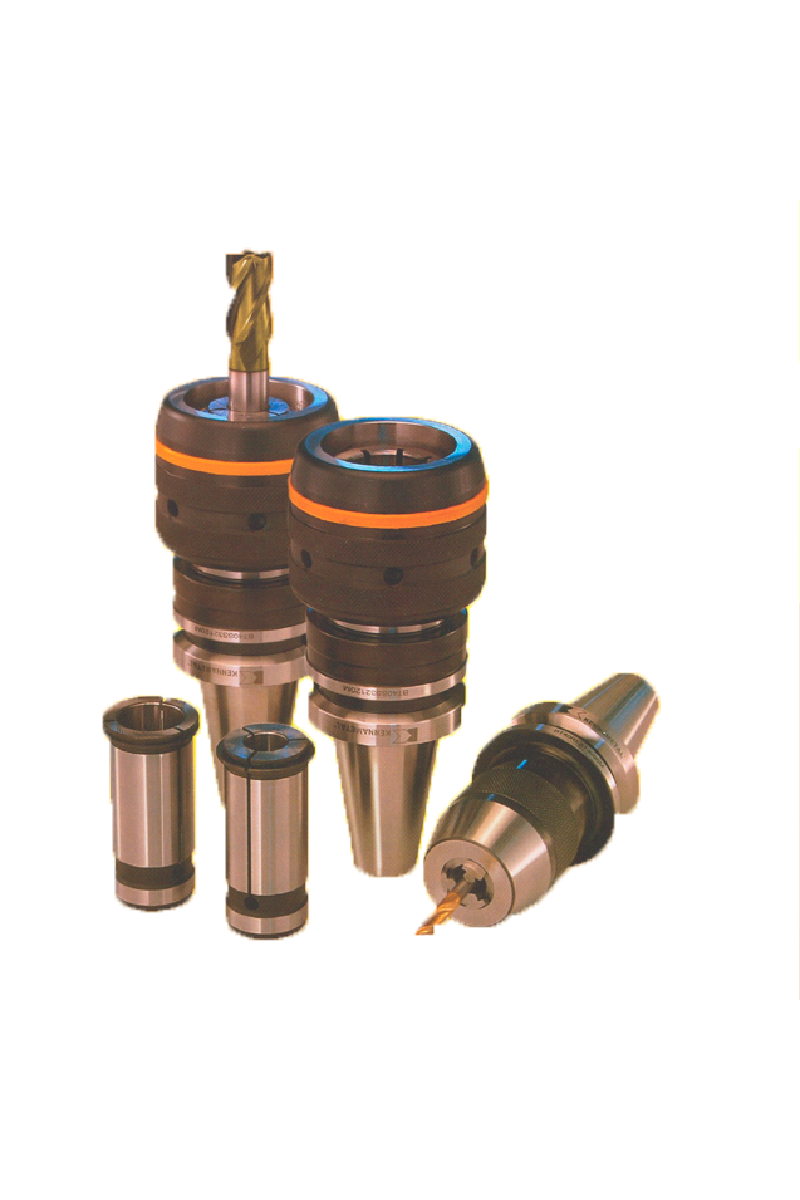

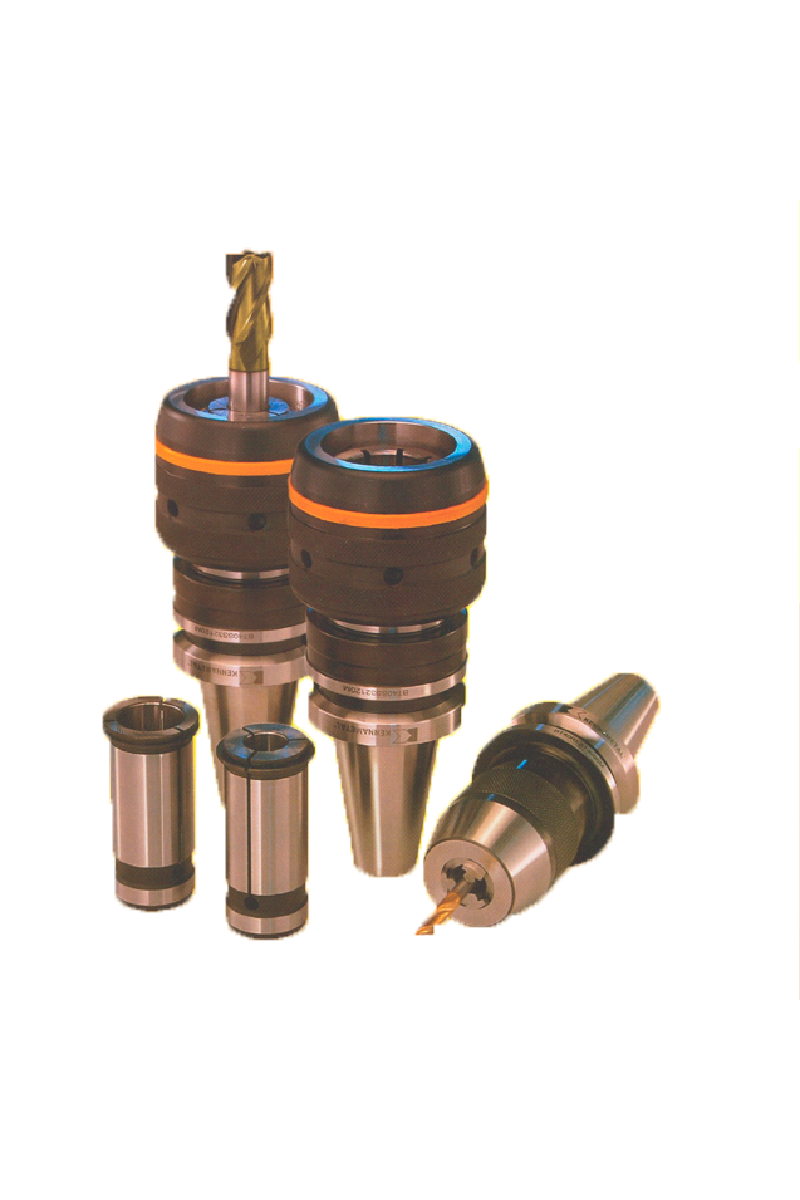

Power Grip Miling Chuck

Milling operation requires a tool holder with good gripping strength and torque transferring capacity. BPTL Power grip milling chuck is developed for heavy milling operations that require high torque for machining.

Read More

Milling operation requires a tool holder with good gripping strength and torque transferring capacity. BPTL Power grip milling chuck is developed for heavy milling operations that require high torque for machining.

Read More

Power grip milling chuck has a special mechanism for holding the tool; it uses taper roller bearings to hold the tool in place. The tool is held in the sleeve of the chuck; the sleeve is ground in line with the chuck and is an integral part of the holder.

The sleeve of the chuck acts as a collet and is compressed around the shank of the tool when the tapered roller bearing in the retainer is turned around the sleeve. The taper roller bearings held in the retainer are at an angle that matches the taper on the outside of the sleeve, at a slight skew. When rotated the roller bearings track in a helical movement and gradually climb up the shallow taper. Two tapers are forced together and a high, uniform force is created that compresses the sleeve inward to hold the tool. In this chuck, there is no issue of axial drawback, which is also an advantage.

These chucks have better-gripping strength than the ER collet chuck, Endmill adapter, and in certain cases Hydraulic chucks as well. BPTL provides a Power grip milling chuck in two formats, Standard Duty, and Heavy duty. BPTL Power grip collets are also available which increases the utility of this chuck. BPTL provides a Power grip milling chuck in the tapers of BT (MAS403/JIS B 6339) and DV (DIN 69871).