What is an Annular Cutter?

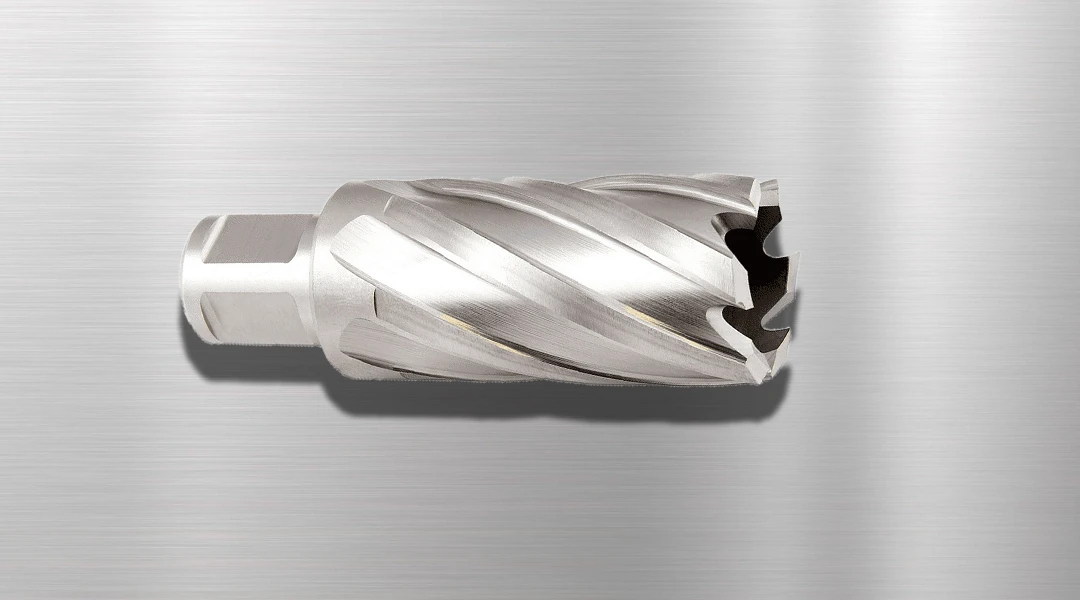

An annular cutter is a unique kind of hole-making tool. It can cut metal similar to a hole saw. Annular cutters differ from many other hole-making methods in that it only makes a groove around the edge of the hole, removing a solid slug from the centre of the hole.

It should be noted right now that annular cutters have a big disadvantage when it comes to automation. Particularly, they don’t always reliably eject the core slug. You must either set up a system to test whether the slug was correctly expelled with a touch sensor that will stop the g-code program if the slug is caught in the bore or make sure the operator is keeping an eye out for that.

Then, why ever use an Annular Cutter?

Annular cutters have some benefits for a specific set of applications. They require the least horsepower, for instance, on smaller, lower-powered equipment (like a Bridgeport scale machine). The annular cutter might just save your bacon if your machine lacks the horsepower to operate a huge twist drill or indexable drill.

Of course, you could just use an endmill to interpolate the hole, but the annular cutter is substantially quicker. And their market niche is essentially defined by the mix of speed and lesser horsepower. They work well on drill presses and other second-hand machines with lower power.

How to use an Annular Cutter?

Annular cutters have a Weldon-style shank and are designed to be used with chucks or set screw holders with flat engagement. They also feature a central button that discharges the slug. The pin is sometimes known as an “ejector pin” or a “pilot pin.”

The pin rests on top of the slug as the cutter descends into the hole. As you keep withdrawing, a stop in the machine will finally push up against the pin and eject the slug. Some designs have a spring to inject the slug so they can function on a machine that hasn’t been updated. The pin on some models also determines whether cutting fluid is released.

Annular Cutter Feeds and Speeds

For the longest tool life and optimum performance, you should use annular cutters at the appropriate feeds and speeds, just like you would with any other type of cutter.

Conclusion

Annular cutters can significantly reduce the amount of time that low-horsepower machines must spend using more powerful cutting tools. They require some maintenance, but they could be the perfect answer to your hole-making problems.