Description

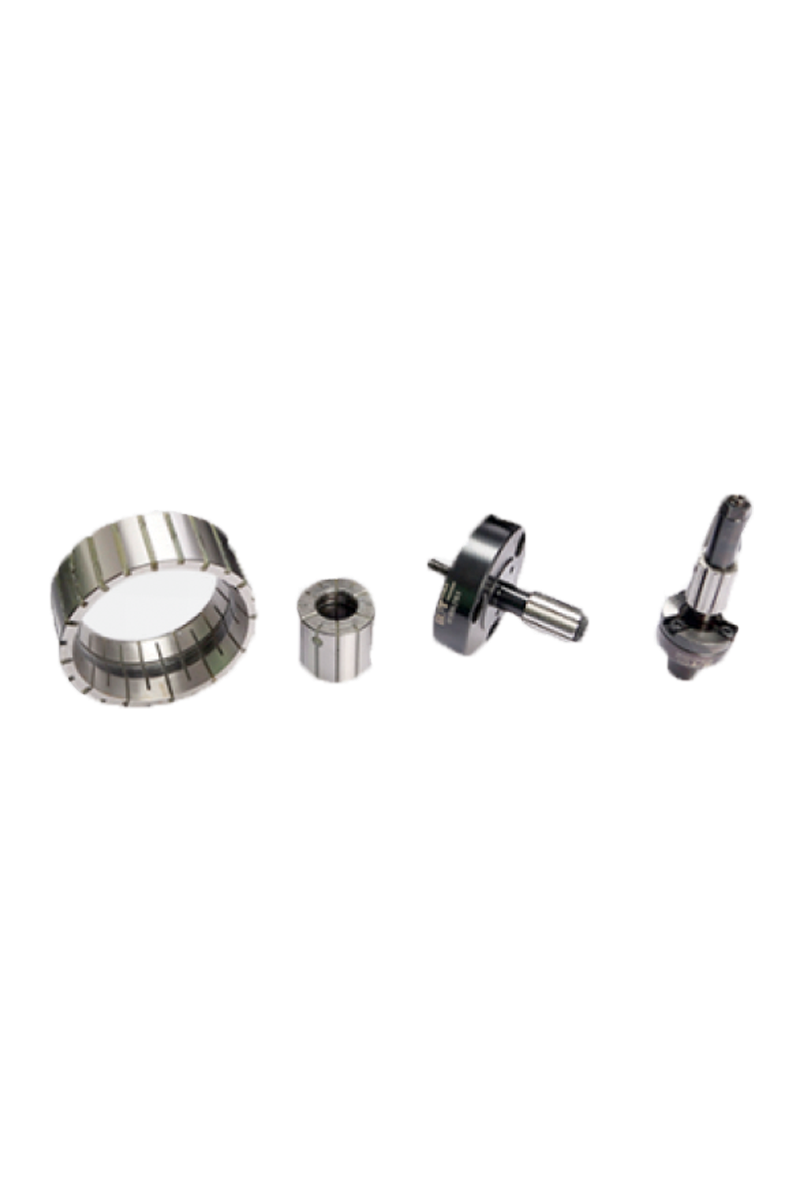

BPTL provides the latest range of expanding mandrels and sleeves that are capable of automatically clamping in the component bores. They work on the principle of double angle contact, which provides precise expansion. They are highly accurate and provide sufficient holding strength to perform heavy machining operations as well.

BPTL provides the following designs of expanding mandrel:

- 1. Face plate drawbar operated: This design can be used on the machines with drawbar facility. In this design, the mandrel is mounted to the faceplate or face of the chuck. This method is simple, direct and has good repeatability. It is suitable for large, medium or small production runs. It is suitable for both turning and grinding operations. In this design natural pull back action of the sleeve ensures the component is hard against the locating face. It is provided with an over expansion stop in the expander pin to avoid over-stressing on the expanding sleeve.

- 2. Spigot drawbar operated: This design can be used on the machines with drawbar facility. In this design the mandrel is mounted using the spigot which is extending backwards of the faceplate. The mandrel is hold in place with the help of soft jaws of the chuck. This method is quick on installation and removal of mandrel. Both turning and grinding operations are supported by this design. This design also provides an over expansion stop in the expander pin to avoid over-stressing on the expanding sleeve.

- 3. Between centres: This design is generally mounted between two 60 degree centres, and is driven from drive flats with a carrier or drive plates. This design is hand operated or by use of conventional spanners. These mandrels are generally used for small batch grinding operations. They are also used for inspection purposes.

- 4. Nut operated faceplate (Modular design): The faceplate thread operated expanding mandrel can be used on any machine with no drawbar facility, for general turning and grinding operations. Adaptor plates can be made to suit the machine mounting if necessary. The natural pull-back action of the sleeve ensures the component is hard against the location face.

- 5. Cantilever operated: This mandrel is used on machines with the facility of morse taper mounting. These mandrels can be used for general turning or grinding operations. These are specifically useful for blind bores. They are hand operated by use of a 'C' spanner, and are suitable for small batch work. There is an over-expansion stop built into the expander pin to avoid overstressing the expanding sleeve.

BPTL provides sleeves in two types, ‘Standard type’ and ‘Flush type’ sleeves. Both these sleeves are double contact and standard sizes are available as per catalogue. The only difference in the design of these two sleeves is at the expanding pin head. In ‘Flush type’, expanding pin head is flushed with the face of the sleeve and in the ‘Standard type’ it is projected outwards.

Sleeves are provided in comprehensive range of designs to meet the varying conditions of work holding. This range includes:

- Flush types in all lengths

- Half-length types

- Double length types

- Segmented types for large expansion and excessive driving requirements

- Serrated types for spline location and holding on internal gear forms (either minor or pitch line diameter location) and types for holding on irregular forms.

- Types to give expansion up to 6.3mm (1/4") on diameter for large diameter components